Make

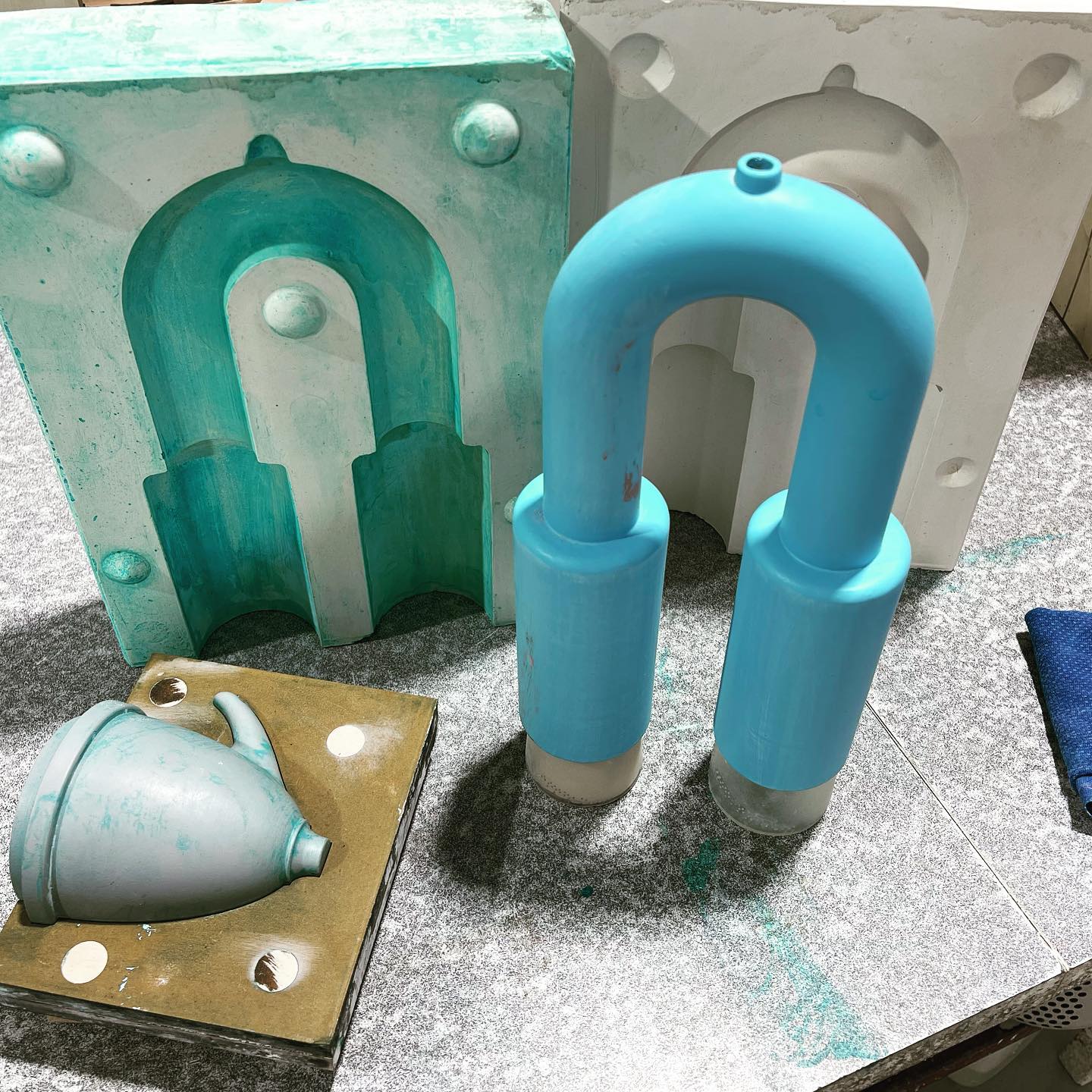

In our studio all work is created by hand using the 300-year-old techniques of mould making and slip casting. Liquid clay, called slip, is poured into a porous Plaster Of Paris mould, which has a cavity in the shape of the desired object. Then the object inside the mould is cast for a period of minutes or hours, depending on the thickness required for the design. After the desired time, the residual slip is poured out and recycled.

The soft object left inside the mould is allowed to firm as water continues to be absorbed by the mould, then after an appropriate length of time the relatively firm object is removed from the mould, dried and then bisque fired at around 1000°C to render it insoluble. It is then coated in a glaze solution and fired a second time at around 1300°C – the highest heat for any domestic ceramic - to change the design to porcelain. This intricate process ensures the perfect formation of each design.